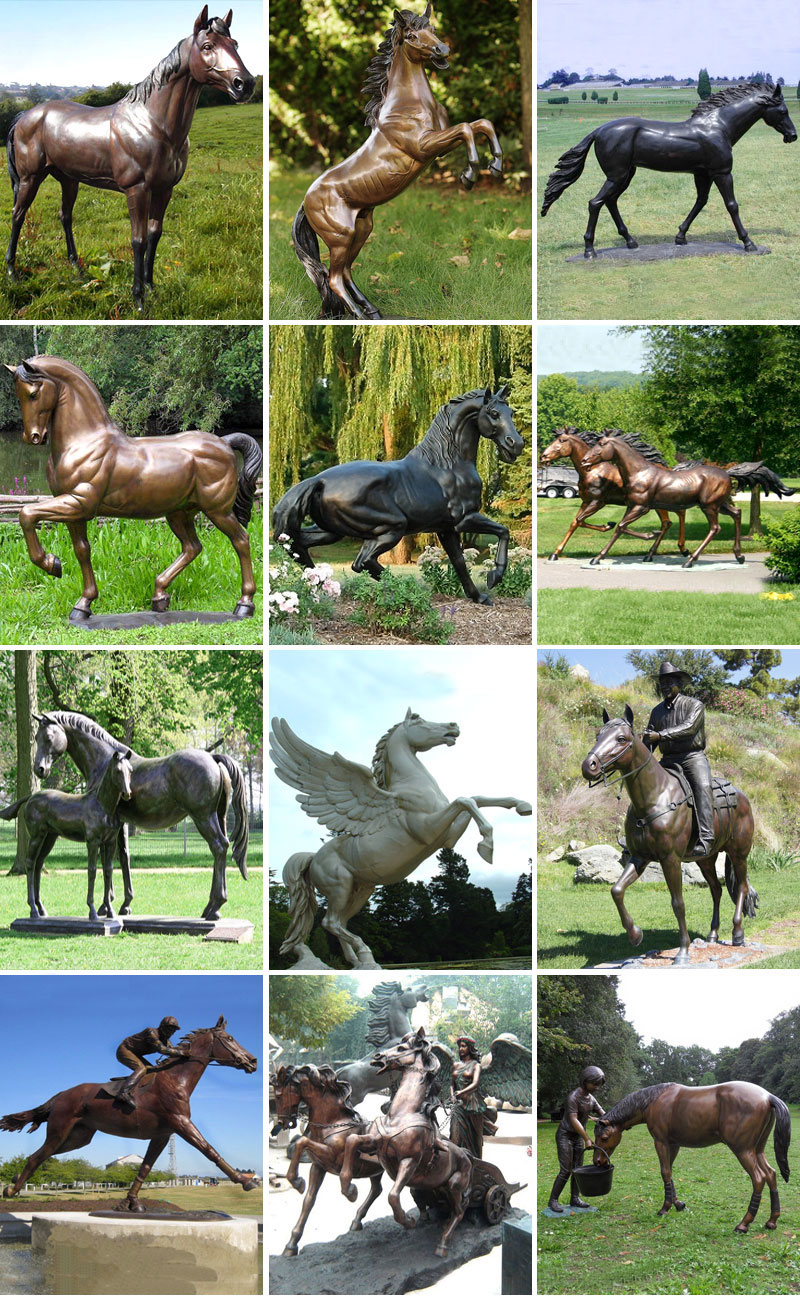

You Fine was founded since 1983, which is specialized in bronze casting with a great expanding in all fields of Sculpting Business during the past 30 years.Mainly operating production contains Standing Horse,Jumping Horse,Horse Racing ,Horse Trophies ,Horse Figurines

No matter the style you are looking for, You Fine is sure to have many selections to suit your personal decor and lifestyle for bronze horse statue &sculpture .

A good quality bronze horse statue, not only need nice design, but also good casting quality. We are always proud of our casting quality. With advanced lost-wax casting, finest welding & chasing skills, excellent patina and best bronze raw material, we always supply art-quality casting.

1.You supply us with several photographs with dimensions.

2.Once we agree on a photo to base the design on, we will begin to make the clay mold.

3.As the mold is being made, we are in constant contact with you showing the progress.

4.Changes and alterations are made to the mold. The mold will only be casted after your approval

5.The sculpture is cast in Bronze.custom bronze patriotic sculpture.

6.Patina and a protective wax coating are hand-applied.

7.We Deliver, You Enjoy!

A horse statue will last forever

This is why it is very important to carefully choose a competent and professional artist to design and create a high quality statue that will truly have an impact and last forever.

You Fine Art Sculpture owns the most efficient and professional artist team, they have finished more than 350 different custom bronze horse statue projects in the past 6 years.

We make bronze horse statues for treasured loved ones who have made a lasting impression on others. At You Fine Art Sculpture Custom Bronze Sculpture, we involve you in all decision making and capture in exquisite detail exactly what you need and how you want it.

The Process of Lost Wax Casting for Bronze Horse Statue

Step 1 Clay Model Making

our artists team make a clay model at first, which is 100% based on customers’ request.

Step 2 Silicon Rubber Mold

This step is by far the most critical. All the detail which appears on the bronze sculpture must be captured in the mold. The mold (depending on the size of the sculpture) is cut into sections for casting.

Step 3 Wax Making and Chasing

Molten wax is poured into the mold to form layers of wax. This wax model is an exact duplicate of the original casting. Then the wax is pulled from the mold and hand chased (re-detailed) by a skilled artisan. Although the artist reproduces the original artwork, each piece may slightly differ from the next.

Wax rods (gates) and pouring cup are attached to the wax casting in just the right positions. This will assure a full pour.

Step 4 Ceramic Shell Making

In a temperature controlled climate of 72 degrees Fahrenheit, the wax casting is dipped into Investment liquid several times. On the first dip a fine powder is applied. On the next dip of course, ceramic sand will be applied. This step is repeated several times, each increasing the coarseness of the material to create the ceramic mold. Between each dip, the ceramic layer must cure (dry) before another layer can be applied.

Step 5 Burn-Out and Casting

The ceramic shell is placed in a kiln and fired. The shell bakes and the wax is melted (lost) from the shell. This creates a hollow ceramic shell mold. Thus the term “Lost Wax.” Immediately the molten bronze is poured into the shell. At the time of pouring, the bronze is 2100 degrees Fahrenheit.

Step 6 Shell Removing

After the casting has cooled several hours, the shell is carefully broken away leaving the unfinished bronze.

Step 7 Welding & Chasing

with their finest welding&chasing skills, our professional craftsmen assemble the pieces together and show all details of original for us.

Step 8 Patina

According to customers’ requests, we make unique and art-quality patina which can stand for tens of years.